How to Use a Gutter Machine

Posted by Steven on December 05, 2024

Gutter machines allow workers to produce gutters at 35 to 45 feet per minute. They are a must for anyone looking to start or continue a gutter-making business. These seamless gutter machines allow workers to customize gutters to the desired shape and size. Because they allow gutter production without leaving the work site, they boost productivity while lowering material, and labor expenses.

Types of Gutter Machines

It is important to know the different types of gutter machines. Different gutter machines produce different gutters.

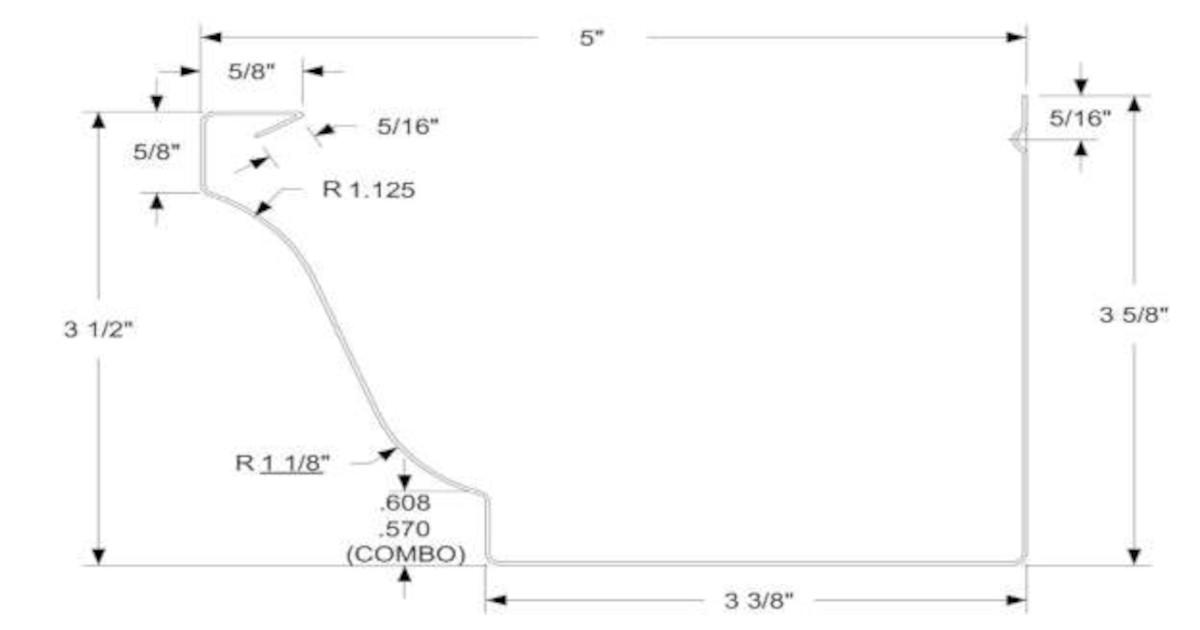

K-Style Gutter Machine

K-style or ogee gutters are the most common type in the United States. They have a flat bottom with vertical back and front walls. Their shape resembles colonial-style crown molding. They are easier to clean because they don't have sharp corners. This K-style gutter equipment is great for producing a simple and effective gutter.

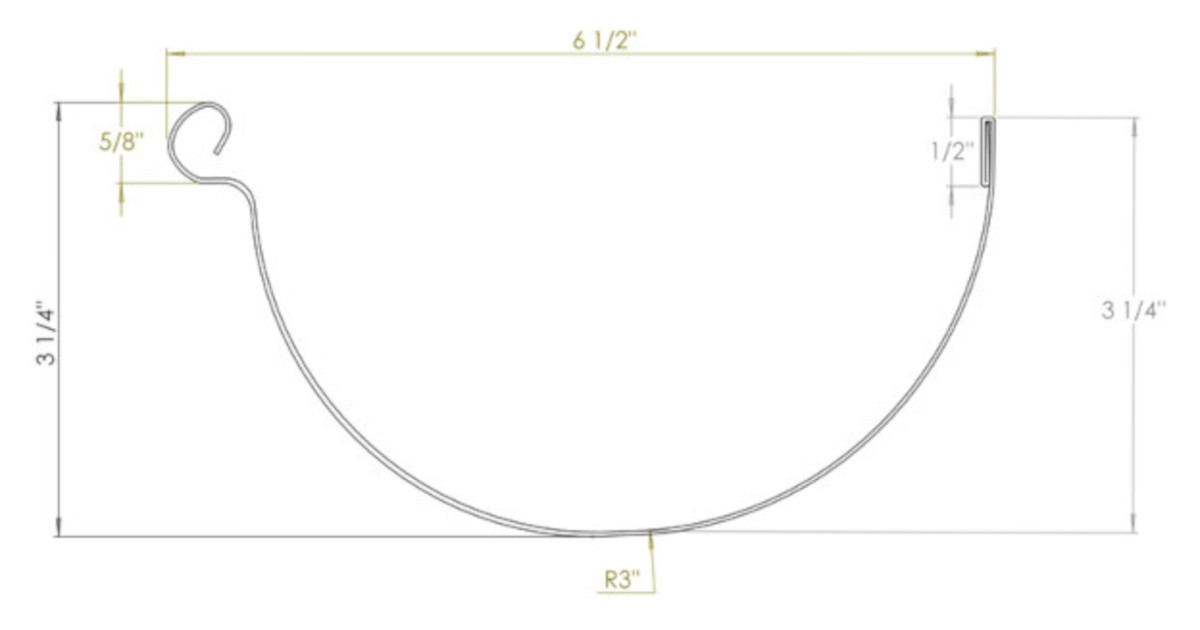

Half-Round Gutter Machine

Half-round gutters are known for their semicircular shape. These were more common in homes built before the 1950s. Half-round gutters are produced to repair historic homes or recreate the architectural look. The only issue is they are harder to install because of their shape.

Operating the Gutter Machine

To safely operate the machine, follow the listed steps for high-quality production of seamless gutters.

- Setup: Place the machine on a level and stable surface. Inspect the electrical components and check for signs of damage. Ensure the machine's safe covers keep dirt, dust, and foreign objects out.

- Preparation: Secure your metal coil to the machine. Before feeding the metal into the machine, cut ears at 3 inches on both corners.

- Power it up:Turn on the machine to ensure everything is working. Gradually feed the metal coil through the machine so it can shape the gutter profile as it goes through. After you cut off the section where the ears were cut, you are ready to continue.

- Quality Control: Monitor: the machine to make sure it is producing gutters with no malfunctions or irregularities. Check the previous gutter for consistency.

- Collect: When the gutter has reached your desired length, use the gutter guillotine to trim the gutter. You need a system in place like a run-out stand to collect the finished gutter pieces. You can purchase run-out stands and other accessories.

- Rinse and Repeat: Repeat the process for each section until you have enough for your project.

- Inspect: Check each section to make sure they meet your standards. Fix any issues immediately to ensure smooth operation.

- Perform Maintenance: See below

- Turn off the Machine: When your project is finished, power down your gutter machine. Put away any material and make sure everything is clean and organized.

Gutter Machine Maintenance and Safety

Here are a few tips to help you maintain your gutter machine and expand its lifespan.

Cleaning

Metal shavings and other dirt will build up in your machine. Clean your gutter machine regularly to avoid blockages or malfunctions. Clean the visible and hard-to-reach areas and make sure that you unplug the machine.

Lubrication

Lubricating your gutter machine reduces friction between moving parts and ensures that it operates smoothly. Specific recommendations for lubrication are typically found in the machine's manual.

Safety First

Wear safety glasses and gloves for protection while operating a gutter-making machine. Avoid using a machine while distracted or fatigued, and never attempt to unblock a machine while it is running.